MIL-DTL-23919C(SH)

3.3.4 O-rings. O-rings for the hub of the base assembly shall be circular rubber rings conforming to

SAE-AMS-P-83461. Sealing grease for installation of the O-rings shall conform to SAE-AS8660.

3.3.5 Fasteners. The fasteners used to attach the assembly to the structure to be protected shall be made from

corrosion-resistant material, preferably nylon.

3.4 Performance requirements.

3.4.1 Accuracy/offset. Performance A cells shall have a normalized measurement within ±10 millivolts DC

compared to the E244 In-Vivo Metric (IVM) standard reference cell, or equivalent standard cell. Performance B cells

shall have a normalized measurement within ±4 millivolts DC as compared to the model E244 IVM standard reference

cell, or equivalent cell. Additionally, the difference between the maximum and minimum potential values of all

Performance B cells being tested shall not exceed 2 millivolts (see 4.5.2).

3.4.2 Additional requirements for performance B cells.

3.4.2.1 Stability and static drift. For Performance B reference cells, the maximum change between any two

reference cell elements shall not exceed 0.6 millivolt DC under constant environmental conditions over 14 days

(see 4.5.3).

3.4.2.2 Temperature linearity. For Performance B reference cells, the maximum absolute difference in slope

between any two reference cell elements shall not exceed 0.035 millivolt DC/°F when tested at temperatures from 40

to 90 °F over 336 hours (see 4.5.4).

3.4.2.3 Water resistivity linearity. For Performance B reference cells, the maximum absolute difference in slope

when plotted on a semi-log graph between any two reference cell elements shall not exceed 0.03 millivolt

DC/log(ohm-centimeter) when tested at water resistivities between 18 ohm-centimeters and 288 ohm-centimeters

(see 4.5.5).

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are classified as follows:

a.

First article inspection (see 4.2).

b.

Conformance inspection (see 4.3).

4.2 First article inspection. When a first article sample is required (see 3.1), inspection shall be performed on

three sample reference cells of each style of configuration. This inspection shall include all tests of 4.5.

4.3 Conformance inspection. Conformance inspection shall include the tests of 4.5.1 to 4.5.5 and 4.5.7 to 4.5.10.

4.3.1 Lot. For the purpose of sampling, a lot shall consist of those reference cells of each specified classification

from the same production run offered for delivery at one time. However, this lot shall not exceed 200 prepared

reference cells.

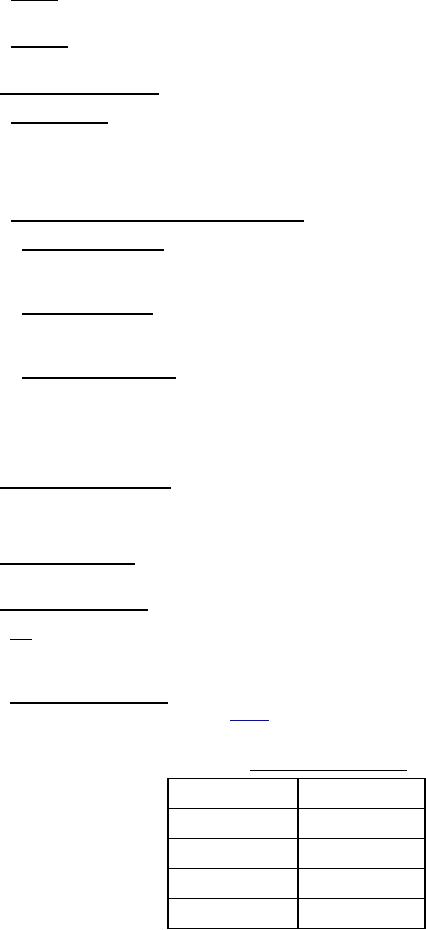

4.3.2 Sampling for examination. From each lot specified in 4.3.1, a minimum of three cells shall be tested,

including one of any unique configuration (see table I).

TABLE I. Sampling for examination.

Lot size

Sample size

3-25

3

26-50

5

51-90

6

91-200

7

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business