MIL-DTL-23919C(SH)

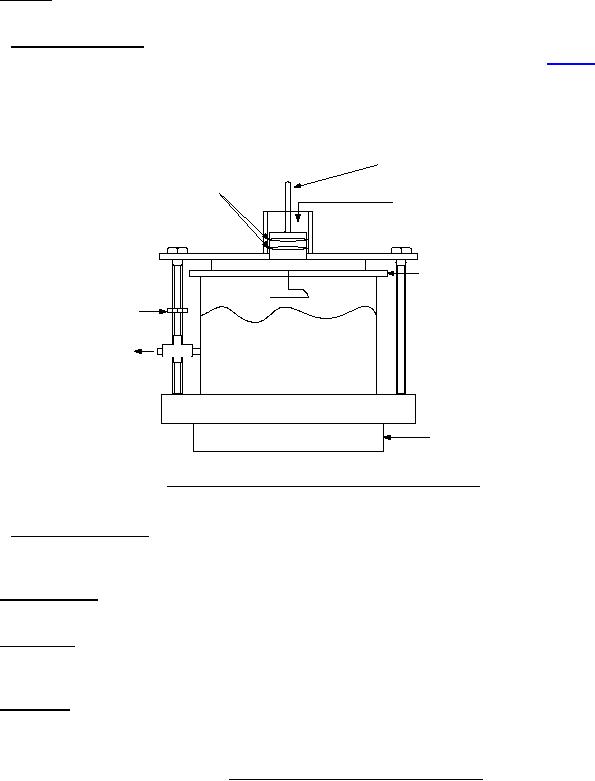

4.5.6 Pressure. Each sample electrode shall be mounted in a pressure test fixture so that the face and mating

surface of the reference cell assembly shall be covered.

4.5.6.1 Class I reference cells. A pressure of 100±10 pounds/inches squared (70300±7030 kilograms/meters

squared) shall be applied to the base, electrode, and pin assembly prior to assembly of the holder (see figure 2). The

tube inserted over the electrode hub and O-rings shall be filled with a colored, translucent liquid containing a

wetting agent (i.e., Windex® or equal). The pressure shall be maintained for 2 minutes. No bubbles shall appear.

Additionally, no deformation shall be present on the reference electrode or assembly.

BASE AND PIN

ASS'Y ONLY

"O'-RING

FILL CAVITY WITH

SOAPY WATER

SOLUTION

GASKET

VALVE

TO

HELIUM

SOURCE

TEST

FIXTURE

FIGURE 2. Sample pressure test setup for class I reference cells.

4.5.6.2 Class II reference cells. Reference cell pressures are governed by ship specific criteria pertaining to the

test depth of the vessel. Reference cell testing shall meet the requirements of MIL-C-24231, Type II, with the

exception of insulation resistance, continuity, hardness, and dye-penetrant.

4.5.7 Chemical purity. Proper assessment of Ag and AgCl purity shall be conducted. Certification of this

assessment shall be provided.

4.5.8 Surface area. Surface area of a plate style reference cell shall be measured using a calibrated laboratory

ruler. Proper surface area of a mesh style reference cell shall be a mesh size of 40 or finer as illustrated in

ASTM E11.

4.5.9 Service life. When specified (see 6.2), certification of uniform thickness and longevity (life) calculations

shall be provided to support service life requirements. The life shall be based on the weight of AgCl used in the

reference cell. Ensure that the minimum amount of AgCl on cell surface is no less than the value given by:

3 × LeakageCurrent( A) × ServiceLife(sec)

Weight AgCl (mg ) =

1.49

Where: the leakage current is given as the hull polarization value (e.g., 0.85 volt) divided by the input impedance of

the potential measuring circuit (ohms). Note that the amount of AgCl on the reference cell face may typically be

more than this value in order to ensure stable readings. The calculated value is only a minimum.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business